Do you want to know and understand the in-depth details of the SAP ATP Scope of Check, its settings, and industry best practices?

In this blog post, we will discuss in detail the scope of check, which is known as the heart of ATP.

Please dive in for more details.

If you want to have an overview of SAP and its technology, please check out our blog on SAP For Beginners.

While creating a sales order in the SAP system, we can only confirm the quantity on the requested delivery date by using a core component called Product Availability Check.

This is controlled by the “Product Availability Check” controlled by the “Scope of Check.”

The PAC ensures that the desired quantity on the desired date can be made available after considering all past requirements.

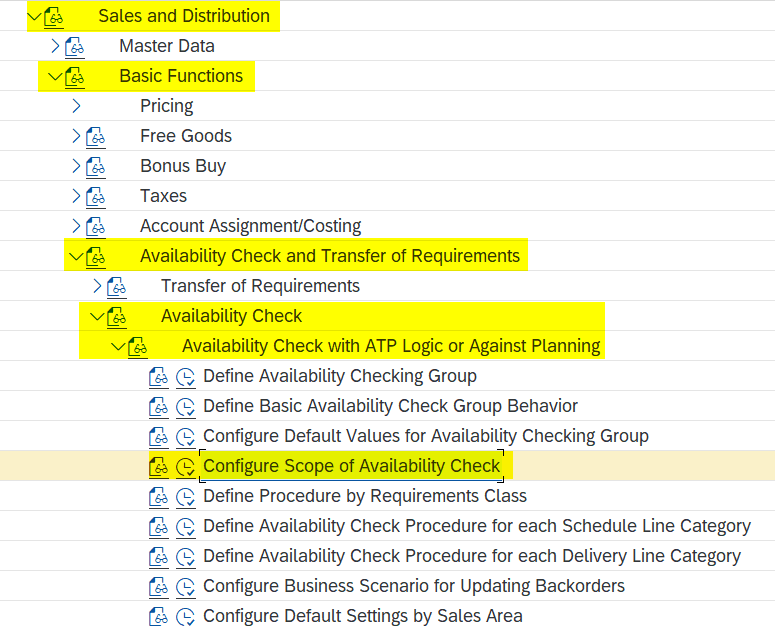

Scope of Check Path:

SPRO > Sales & Distribution > Basic Functions >Availability check and Transfer of Requirements > Availability Check > Availability check with ATP Logic

Scope Check Transaction: OVZ9

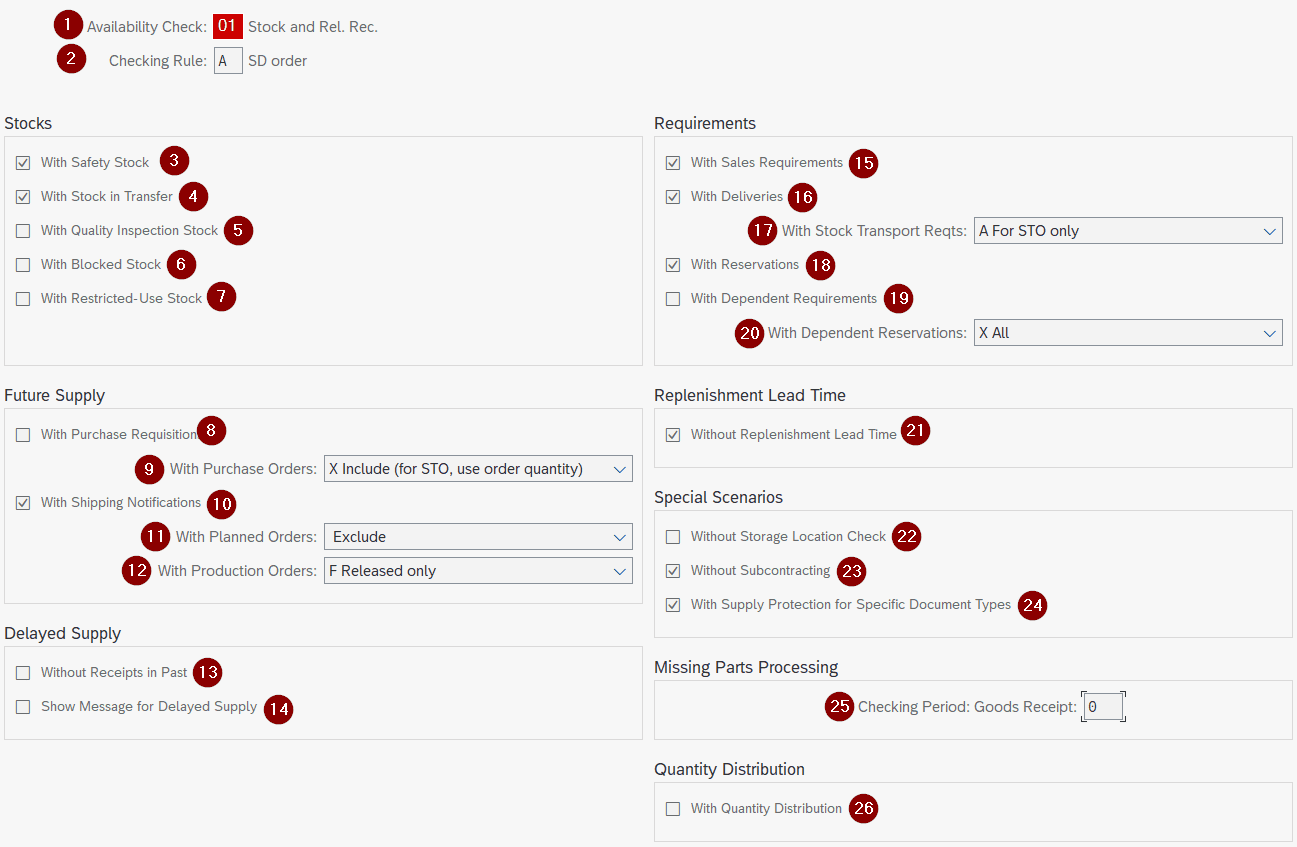

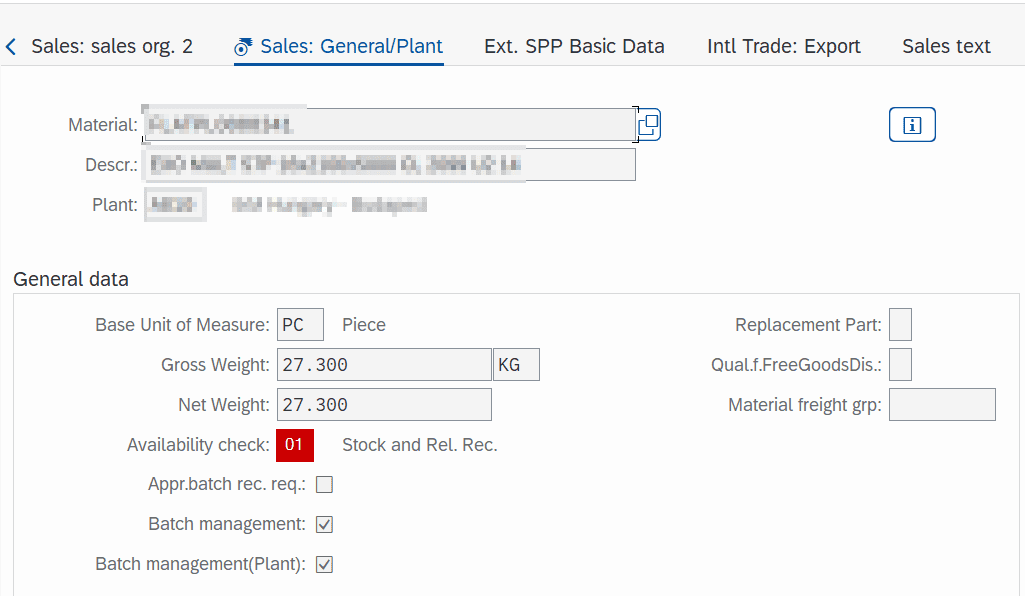

Availability check:

Maintained in the Sales General Plant view of the Material Master. This helps in selecting the combination of the Scope of check.

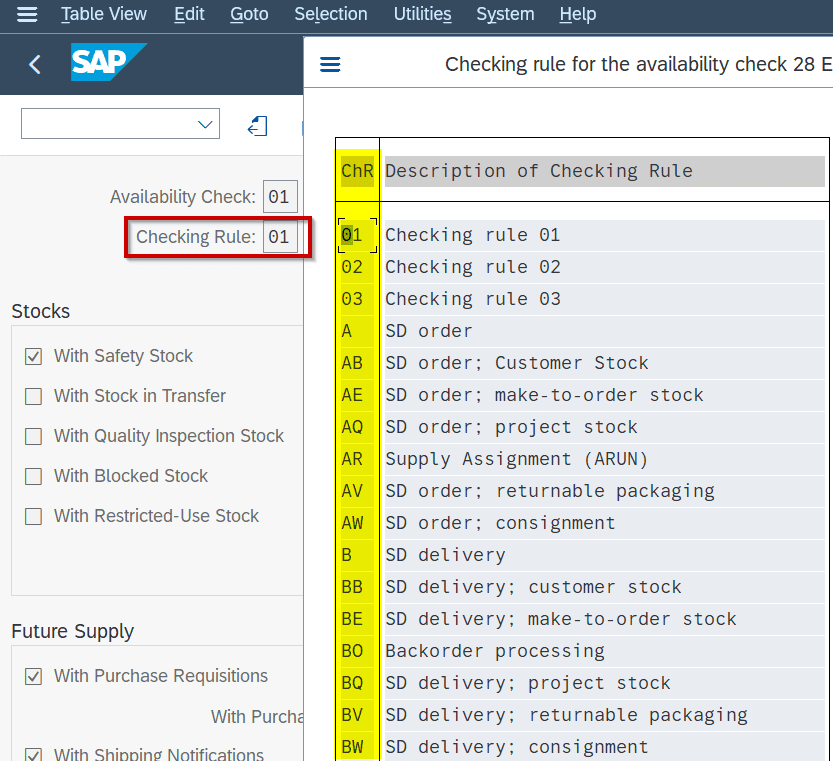

Checking Rule:

This defines the type of document for which we are doing ATP checks.

With safety stock:

Safety stock is a stock that companies reserve to meet emergency demands. This check box signifies whether the safety stock should be considered during ATP.

With stock in transfer:

Sometimes the companies need to do stock transfers between their plants to meet customer demand or do the replenishment process. This check box signifies whether the STO quantity should be considered during ATP.

With quality inspection stock:

Due to various reasons, e.g., stock returns from the customer, stock receipts from the vendor, or stock receipts from the production order, companies want to verify the material before making it available for sale. This process is called the quality inspection process. This check box signifies whether the stock that is in the Quality Inspection should be considered during ATP.

With blocked stock:

This is a kind of stock where companies want to keep the stocks in the blocked stage so that the quantities can not be consumed unless strictly verified.

This check box signifies whether to include blocked stock or not.

With restricted-use stock:

This signifies whether any restricted stocks should be considered during ATP.

With purchase requisitions:

This signifies whether any future supply quantity against open purchase requisitions needs to be considered for ATP.

With Purchase Orders:

This helps in considering the PO quantity or the confirmed quantity to consider during ATP.

With Shipping Notifications:

Whether to consider any Advanced Shipping Notifications received from suppliers for goods receipt.

With Planned orders:

This helps in considering the quantity to be received from either the confirmed or created Planned orders.

With Production orders:

Whether to consider the quantity to be received from the Production orders.

Without receipts in the Past:

Whether to consider the delayed receipt of any materials.

Show messages for Delayed Supply:

This will show a message in case the expected quantity is still not received but is expected to be received soon.

Consider sales requirements:

Every sales order created in the system generates a requirement. This is due to the fact that the system has to consider the current stock and all the receipts or demands so that any incoming orders can be confirmed or unconfirmed based on their actual availability.

This checks whether to consider the requirements generated from already created sales orders.

Consider Delivery requirements:

Similar to sales orders, deliveries that are not completed yet also create requirements in the system. This control checks whether to consider the requirements already generated from the delivery.

With Stock Transport Request:

This checks whether to reduce the quantity that is already assigned to other STOs.

With Reservations:

Whether to consider the material reservations during ATP.

Dependent requirements:

specifies whether to include dependent requirements.

Include/Consider Reservations:

specifies whether to include reservations.

Without Replenishment Lead Time:

This controls whether the system should consider replenishment lead time during ATP or not. RLT is the time within which a product can be ordered and made available for delivery.

E.g., if we don’t have any stock and the RLT is maintained at 5 days and the delivery date is after 2 days, the system will confirm the delivery date the very next day of the RLT, which means the 6th day from today.

If the delivery date is after 5 days, the system confirms on the same day after the 5th day.

Without storage location check:

If we don’t want the ATP check to be done at the storage location level, we can check it here.

Do not consider subcontracting orders:

whether to consider the subcontracting stock during ATP or not.

With Supply Protection for Specific Document Types:

This activates the supply protection for the document types in this ATP check run.

Missing parts checking period:

Specify after how many days the MRP controller should be notified via email if any parts are missing.

Quantity Distribution:

This helps in distributing the requirements of planned orders and production orders during runtime calculation.

Hi, of course this post is in fact pleasant and I have learned lot of things from it concerning blogging. thanks.